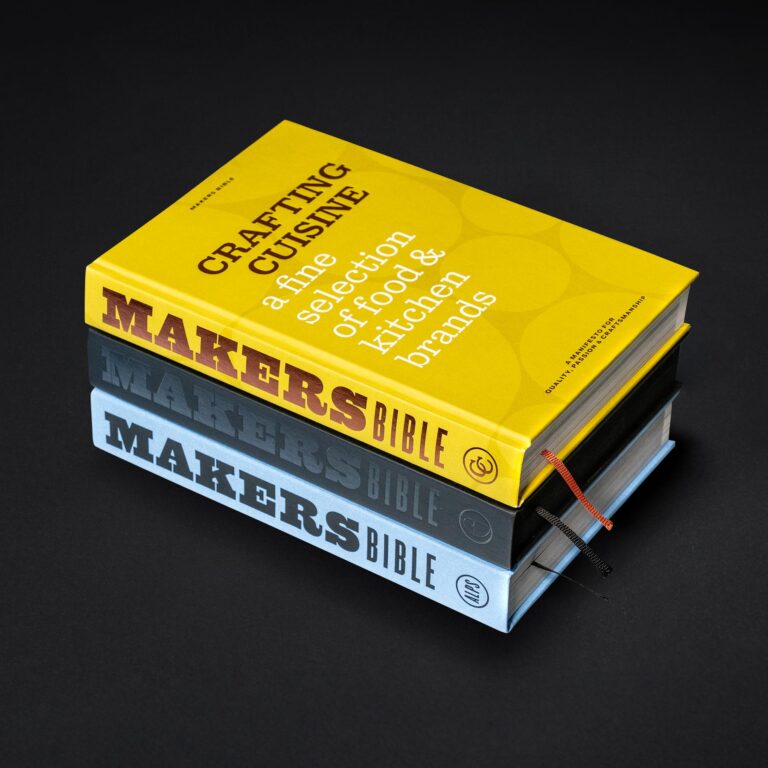

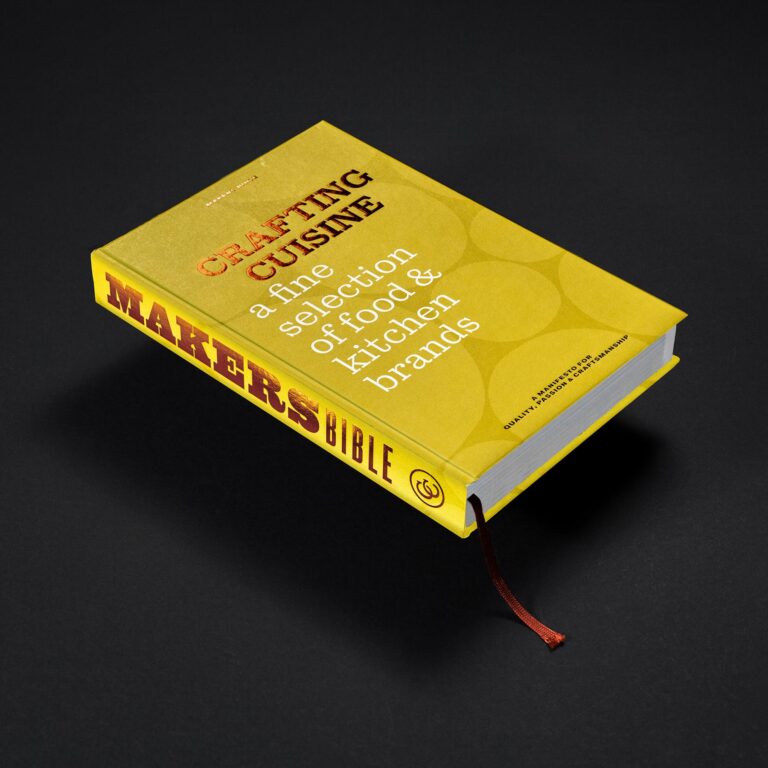

Buying Decisions Shape Supermarket Offers. Those can Shape Landscapes

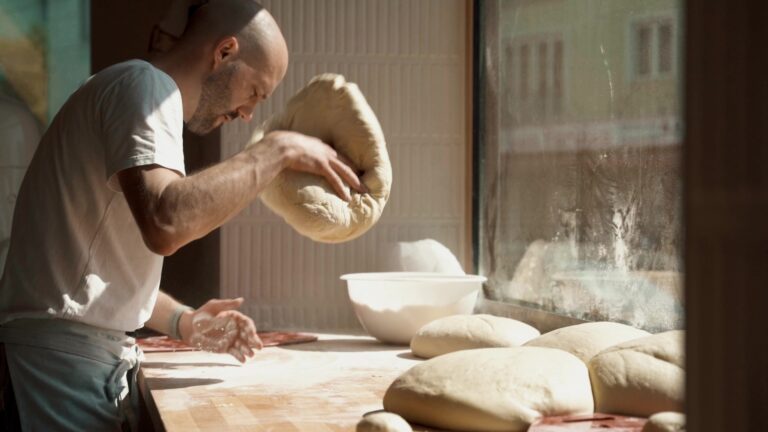

Doing something by hand can change a lot. Buying something handmade out of conviction can do the same. It changes – or has already changed – the way we think. Especially when it comes to our food. What do we buy? Who made it? What can we perhaps grow ourselves? How do our actions and decisions change, first ourselves, then our purchases, then the landscape?